| Available Bearings | Bearing Selector | Technical Info | New Products | |||

Bearing Geometry - Bearing Stiffness || Dynaroll

TECHNICAL PAPERS

Inch Precision

Metric Precision

600 Series

6000 Series

6200 Series

6300 Series

6800 Series

6900 Series

R Series

Thrust Bearings

Stainless Steel Thrust Bearings

Thin Section Bearings

Collar Bearings

Flangette Collar Bearings

Specify by Type

Specify by Desired Dimensions

Specify by Cross-Reference

Specify by Known Part Number

Part Numbering System

TECHNICAL PAPERS

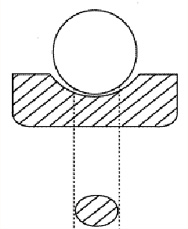

DESIGN FACTORS WHEN USING SMALL BEARINGS, PART 1: BEARING GEOMETRY (Page 5)

This shows the amount of additional axial displacement of a ball bearing raceway as the preload force is increased. The axial stiffness is the inverse of the slope of this curve. It can be seen that higher radial play values lead to higher stiffness. This makes sense since a looser bearing will allow the ball bearing to move higher in the raceway under axial load (higher contact angle), providing more resistance to axial movement. The above curve is important in calculating the amount of preload to apply to a bearing assembly. For miniature ball bearings, typical preloads are in the range of 0.5 to 2 lbs, less for very small bearings. This region of the curve is where the bearing has more compliance and the loads are such that lifetime/wear is not affected. At much higher preloads, approaching the static load rating of the bearing, damage and much reduced lifetime will occur. Note on handling preloaded bearing assemblies: The displacement vs. preload curve is also relevant in understanding how to handle miniature bearing assemblies. At higher preloads, a change in displacement of 1-2 microns (<0.0001 inch) will produce an increase in force of many pounds. What this means is that preloaded assemblies are quite susceptible to shock loads and must be handled accordingly. Many engineers are surprised to find that a small pivot assembly will become brinelled (raceway damage) when dropped from a height of only a few inches onto a lab bench. The radial stiffness, resistance to radial loads on the bearing, varies in the opposite manner to axial stiffness since lower radial play (lower contact angle of the ball) provides more resistance to radial movement. Stiffness of a ball bearing assembly is of interest in designing

for higher resonance frequency or for higher moment resistance.

It should be noted that axial and radial stiffness move oppositely

relative to changes in radial play. The only way to increase

both axial and radial stiffness at the same time is to increase

the amount of preload applied. |

||

Torque

|