| Available Bearings | Bearing Selector | Technical Info | New Products | |||

Ball Bearing Torque Information || Dynaroll

TECHNICAL INFORMATION

TECHNICAL INFO

Overview & Nomenclature

Materials

Cages/Retainers

Shields and Seals

Ball Bearings - Geometry

Ball Bearings - Tolerances

Ball Bearings - Lubrication

Load Rating and Bearing Lifetime

Ball Bearings - Torque

Ball Bearings - Noise

Mounting and Fitting

Assembly Preload

Ball Bearing Handling

Adhesive Practices

Assembly Characteristics

Useful Conversions

Interested in Mechanical Assemblies?

Visit our Assemblies Section

Visit our Assemblies Section

Read our Quality Policy

Overview & Nomenclature

Materials

Cages/Retainers

Shields and Seals

Ball Bearings - Geometry

Ball Bearings - Tolerances

Ball Bearings - Lubrication

Load Rating and Bearing Lifetime

Ball Bearings - Torque

Ball Bearings - Noise

Mounting and Fitting

Assembly Preload

Ball Bearing Handling

Adhesive Practices

Assembly Characteristics

Useful Conversions

Interested in Mechanical Assemblies?

Read our Quality Policy

BEARING TORQUE

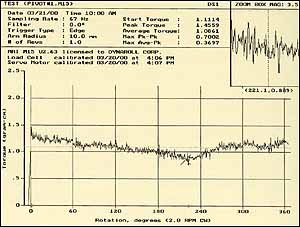

Small diameter (< 20 mm O.D.) deep groove ball bearings have extremely low and uniform torque characteristics. Even when preloaded as part of an assembly, average torque levels of less than 0.5 gm-cm (0.007 oz-in) are common. Typically, torque is dependent on many factors, including ball size, number of balls, retainer type and looseness, radial play, lubricant type and fill percentage, and applied load.

M15 Torque Tester Screenshot |

For more information and a discussion on bearing torque and torque analysis, see Assembly Characteristics.

BEARING TORQUE FACTORS

FACTOR |

TORQUE EFFECT |

Ball size |

Smaller gives lower torque |

Number of balls |

Fewer gives lower torque |

Retainer |

Crown gives lower torque, loose clinch for ribbon type gives lower torque |

Radial play |

Higher gives lower torque |

| Lubricant | Higher viscosity gives higher torque |

| Lubricant fill | Higher percentage gives higher torque |

| Applied load | Higher load gives higher torque |

| The chart below can be used as a simple guide to expected average torque levels for individual bearings with oil lubricant, however, the user must be cautioned that real-life torque values will vary considerably according to the application. | |

AVERAGE BEARING TORQUE (GM-CM)

DYNAROLL BEARING SIZE (Inches Series) |

RETAINER TYPE |

BALL

SIZE Inch (mm) |

#

BALLS |

THRUST

LOAD (gm) |

MAX.

AVG. TORQUE (gm-cm), OIL LUBE @ INDICATED THRUST |

||

RADIAL

PLAY Inches (mm) |

|||||||

MC2 .0001-.0003 .002-.008 |

MC3 .0002-.0004 .005-.010 |

MC5 .0005-.0008 .013-.020 |

|||||

09,0,1,1-4, 1-5 144,

155, 156, 168 |

Crown (W) |

<1/16 |

<13 |

75 |

.18 |

.15 |

.14 |

2-5 |

Ribbon (J) |

1/16 |

6 |

75 |

.18 |

.15 |

.14 |

2-6, 2, 166 |

Ribbon (J) |

1/16 |

<8 |

75 |

.2 |

.16 |

.15 |

188 |

Ribbon (J) |

2 |

8 |

400 |

.63 |

.54 |

.49 |

3 |

Ribbon (J) |

3/32 |

7 |

400 |

.65 |

.55 |

.5 |

4 |

Ribbon (J) |

3/32 |

8 |

400 |

.7 |

.6 |

.55 |