| Available Bearings | Bearing Selector | Technical Info | New Products | |||

Bearing Brinelling and Excessive Force in Bearing Assembly || Bearing noise information from Dynaroll

TECHNICAL INFORMATION

TECHNICAL INFO

Overview & Nomenclature

Materials

Cages/Retainers

Shields and Seals

Ball Bearings - Geometry

Ball Bearings - Tolerances

Ball Bearings - Lubrication

Load Rating and Bearing Lifetime

Ball Bearings - Torque

Ball Bearings - Noise

Mounting and Fitting

Assembly Preload

Ball Bearing Handling

Adhesive Practices

Assembly Characteristics

Useful Conversions

Interested in Mechanical Assemblies?

Visit our Assemblies Section

Visit our Assemblies Section

Read our Quality Policy

Overview & Nomenclature

Materials

Cages/Retainers

Shields and Seals

Ball Bearings - Geometry

Ball Bearings - Tolerances

Ball Bearings - Lubrication

Load Rating and Bearing Lifetime

Ball Bearings - Torque

Ball Bearings - Noise

Mounting and Fitting

Assembly Preload

Ball Bearing Handling

Adhesive Practices

Assembly Characteristics

Useful Conversions

Interested in Mechanical Assemblies?

Read our Quality Policy

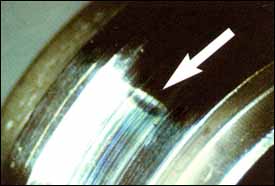

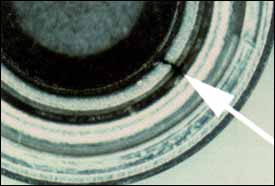

BEARING BRINELLING

EXCESSIVE FORCE

The most common cause of small bearing failure is excessive force applied during assembly, which usually results in the following adverse effects on bearing performance:

| ||||||||||||||||||||||