| Available Bearings | Bearing Selector | Technical Info | New Products | |||

MicroTorque™ Ball Bearings Torque Testing || Dynaroll

TECHNICAL PAPERS

Inch Precision

Metric Precision

600 Series

6000 Series

6200 Series

6300 Series

6800 Series

6900 Series

R Series

Thrust Bearings

Stainless Steel Thrust Bearings

Thin Section Bearings

Collar Bearings

Flangette Collar Bearings

Specify by Type

Specify by Desired Dimensions

Specify by Cross-Reference

Specify by Known Part Number

Part Numbering System

TECHNICAL PAPERS

PRINCIPLES OF MicroTorque™ BALL BEARINGS TORQUE TESTING

|

By Simon Harrison, Ph.D. |

||

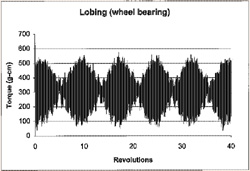

MicroTorque

testing is a deceptively simple method to accurately determine the

“quality” of a rotating part. A source of accurate,

slow, vibration-free rotation is applied to one component of a rotating

part while measuring the force exerted by the opposite component.

The essence of the test is that it is performed at very low speeds,

typically 2 RPM, but in some cases as low as 0.001 RPM. At these

very low speeds, there is no vibration to mask the very small changes

in transmitted force that are caused by microscopic internal inconsistencies

during rotation. When such a rotation system is coupled to a sensitive

force-measuring load cell, the system can detect the smallest variations

caused by bearing brinelling, contamination, raceway misalignment,

lobing and many other issues. Results are graphically displayed

on an easy-to-read trace. MicroTorque

testing is a deceptively simple method to accurately determine the

“quality” of a rotating part. A source of accurate,

slow, vibration-free rotation is applied to one component of a rotating

part while measuring the force exerted by the opposite component.

The essence of the test is that it is performed at very low speeds,

typically 2 RPM, but in some cases as low as 0.001 RPM. At these

very low speeds, there is no vibration to mask the very small changes

in transmitted force that are caused by microscopic internal inconsistencies

during rotation. When such a rotation system is coupled to a sensitive

force-measuring load cell, the system can detect the smallest variations

caused by bearing brinelling, contamination, raceway misalignment,

lobing and many other issues. Results are graphically displayed

on an easy-to-read trace. The purpose of this article is to introduce

the reader to the concept of MicroTorque testing and to present

some analytical results from tests on parts with different rotational

problems. All measurements were taken using an M15W MicroTorque™

tester from Measurement Research, Inc.

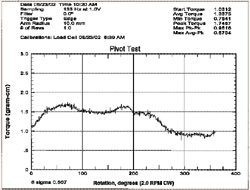

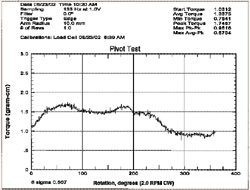

Normal Test Trace Normal test – A “normal” test, like beauty, is in the eye of the beholder. The M15 is a very sensitive device and a perfectly made part may show many small variations during rotation. The important thing is to decide what is important to the application. The test shown here is typical of a disk drive pivot, showing even rotation over 360°. Small irregularities and the grease hash do not indicate any problems. In a typical ball bearing the inner race must rotate 3-4 complete revolutions relative to the outer race before the balls have moved around the raceways once. This means that consecutive 360° tests of the same part actually have different starting positions for the balls, causing apparent torque variation.

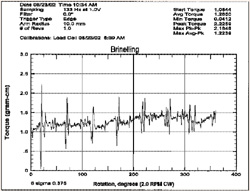

Brinelling Test Trace

Conclusion The MicroTorque tester is a versatile

and powerful tool that can be used to pinpoint a number of rotational

faults. The traces shown in this article show simple effects,

but further analysis of test data, including frequency domain,

can expose great detail of the internal structure of any rotating

part. |

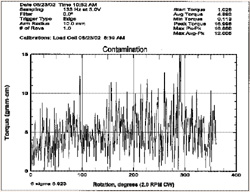

Contamination

Test Trace

Contamination

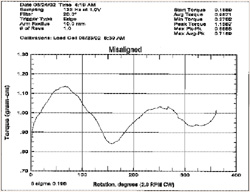

Test Trace  Misalignment

Test Trace

Misalignment

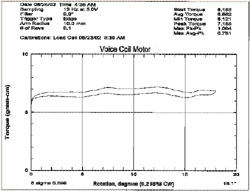

Test Trace VCM Test Trace

VCM Test Trace