| Available Bearings | Bearing Selector | Technical Info | New Products | |||

Ball Bearing Assembly Raceway Misalignment || Dynaroll

TECHNICAL INFORMATION

TECHNICAL INFO

Overview & Nomenclature

Materials

Cages/Retainers

Shields and Seals

Ball Bearings - Geometry

Ball Bearings - Tolerances

Ball Bearings - Lubrication

Load Rating and Bearing Lifetime

Ball Bearings - Torque

Ball Bearings - Noise

Mounting and Fitting

Assembly Preload

Ball Bearing Handling

Adhesive Practices

Assembly Characteristics

Useful Conversions

Interested in Mechanical Assemblies?

Visit our Assemblies Section

Visit our Assemblies Section

Read our Quality Policy

Overview & Nomenclature

Materials

Cages/Retainers

Shields and Seals

Ball Bearings - Geometry

Ball Bearings - Tolerances

Ball Bearings - Lubrication

Load Rating and Bearing Lifetime

Ball Bearings - Torque

Ball Bearings - Noise

Mounting and Fitting

Assembly Preload

Ball Bearing Handling

Adhesive Practices

Assembly Characteristics

Useful Conversions

Interested in Mechanical Assemblies?

Read our Quality Policy

ASSEMBLY CHARACTERISTICS

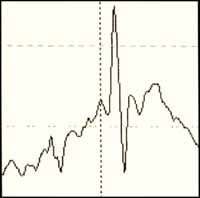

RACEWAY MISALIGNMENT

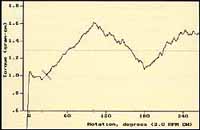

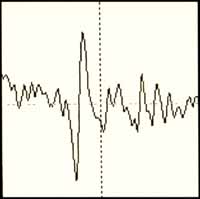

An analysis of continuous rotating torque over 360° or more can be a powerful tool in determining a variety of application-related bearing problems. MicroTorque™ testers manufactured by Measurement Research, Inc. have torque resolution to 10 mg-mm (0.000014 oz-in) and can show raceway damage, contamination, misalignment and lubricant issues in small bearing assemblies. |

|||||||||||

General Note: An analysis of periodic factors of the torque can show different contributions from bearing cage, grease and other elements.To interpret these results, it is necessary to know internal bearing characteristics, and over-analysis is cautioned. |

|||||||||||