| Available Bearings | Bearing Selector | Technical Info | New Products | |||

Dynaroll Ball Bearings Contract Manufacturing

CONTRACT MANUFACTURING

MECHANICAL ASSEMBLIES

Assemblies Overview

Brochures

Applications

Assembly & Manufacturing

Quality Systems

Capabilities

Materials Management

Contract Manufacturing

Mechanical Testing Lab

Design Services

Quality Policy

CONTRACT MANUFACTURING

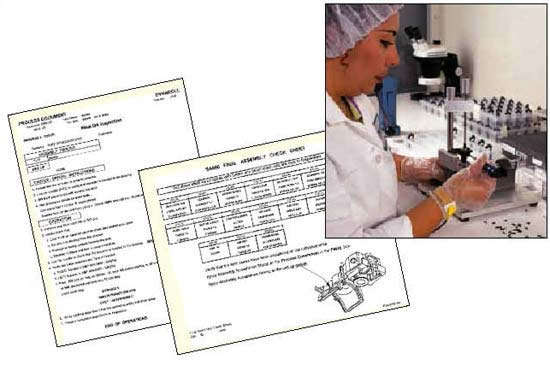

Dynaroll is a contract manufacturer of precision assemblies for medical, aerospace, computer peripheral, automation and other industies where out-sourcing of special mechanical assembly is an advantage. Customers basic application become turn-key design, executed under ISO-9001 process control.

DESIGN VALIDATION

Once the design process is complete (see section on Dynaroll design services), a complete validation can be undertaken to ensure that all design objectives have been met. |

|

ASSEMBLY

Dynaroll has manufactured assemblies for many different industries. After it receives a manufacturing order, Dynaroll personnel use any number of in-house capabilities and quality systems to ensure that the parts are made to the highest possible standard. |

|

INSPECTION

|

|

RECORDKEEPING

|

|